Not set: Position of tool change will not be set, machine will pause when tool change occurs. We define position coordinates of tool change. This is often used with ATC where tool length offset is known in advance. Tool Offset From Tool Table: After tool change, tool length offset value is “taken” from tool table. Measure Tool Length: After tool change, tool length offset is measured using fixed tool length sensor.

Not Used: Tool offset will not be measured. We define if Tool Offset will be set or measured for each newly changed tool. If this option is enabled and G43 is active then it will automatically adjust to changed tool. (no need for G01 X10 Y0 line because of auto return)Īuto Compensate: By g-code standard G43 offset will not change if tool is changed. T2 M6 (change tool with with auto return on) G01 X10 Y0 (cut to X10 Y0 with first tool) T2 M6 (change tool tool with auto return off) By g-code standard g-code return moves should be in g-code program but are often not. This option is useful, to load G-Code from another machine without error.Īuto Return: This depends on your g-code. Default values from tool with number 0 are used instead. Use Default Tool: If G-Code tool numbers are not in the tool table an error is reported. Reset Active Tool: Resets currently active tool at beginning of program. Skip Already Active Tool: If tool with number N is already mounted then TN M6 g-code will be ignored and tool change will not occur. If spindle is controlled through controller then this pause is not needed. During this pause we can turn spindle on manually. Second pause is before cutting (after tool change). During this pause we can turn off spindle manually. Pause For Spindle: Machine will pause after cutting (before tool change). During this pause we will manually change tool. Pause: Machine will pause at tool change position. Stop: Machine will stop at tool change position and will not resume. Z Axis First: Usually you want to move Z axis first, before X and Y. Here we set how we want our machine to “behave” during Tool change.Įnable: This enables tool change procedure.

We will describe individual settings of each group. Tool Change settings are divided into three setting groups: Tool change, Tool offset and Position. Tool Change settings are located in File/Settings/Tool Table/Tool Change. In this tutorial we will focus mainly on Tool Change settings. This will be learning content in upcoming tutorial. Tool Change ATC feature will not be described and used in this tutorial. Tool table, Tool change, Tool change ATC and Tool sensor. If you click File/Settings you can see there are four feature settings using word tool. In the beginning we will determine how we want to machine our workpiece, and base our settings configuration on it.īut first we will describe and clarify Tool Change feature settings.

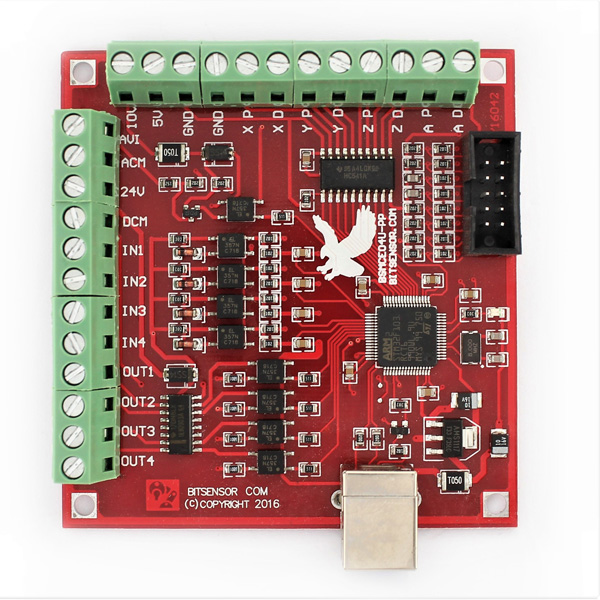

CNC USB CONTROLLER CONTROL ROLE SOFTWARE

The purpose of this tutorial is to clear out some facts about tool change, and to demonstrate tool change procedure during machining of an actual workpiece using Planet CNC software and Planet CNC controller. Tool Change procedure with Fixed Tool Sensor tutorial That will include tool change operations. Through whole machining process, we can machine our work piece with just one tool or we can machine it with many tools. The table, it doesn’t have fixed position. Movable Sensor: For setting ‘Offset Current Z’ at the top surface of work material. Gives us position of the tool tip in absolute coordinates. Difference between Fixed Tool sensor and Movable sensor:įixed Tool Sensor: Used for measuring ‘Tool Offset’.

0 kommentar(er)

0 kommentar(er)